T40 O-RING Mechanical seal

Description:

Temperature: -20℃ to +180℃

Pressure: ≤2.5MPa

Speed: ≤15m/s

Operational Conditions:

Stationary Ring: Silicon Carbide, TC

Rotary Ring: Carbon, Silicon Carbide, TC

Secondary Seal: NBR, EPDM, Viton

Spring and Metal Parts: Steel

Materials:

Standard: 24DINL

Alternative: T21

Applications:

Clean water,

Sewage water

Oil and other moderately corrosive fluids

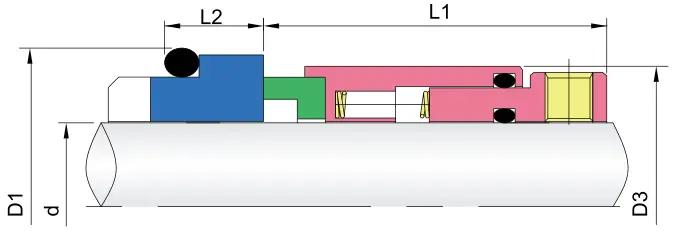

| d (mm) | Inch Size | D3 | D1 | L1 | L2 |

| 18 | 32.5 | 33 | 30 | 100 | |

| 19 | 0.750 | 33.5 | 35 | 30 | 10 |

| 20 | 34.5 | 35 | 30 | 10 | |

| 22 | 36.5 | 37 | 30 | 10 | |

| 24 | 0.875 | 38.5 | 39 | 30 | 10 |

| 25 | 39.5 | 40 | 30 | 10 | |

| 1.000 | 39.5 | 43 | 30 | 10 | |

| 28 | 42.5 | 43 | 32.5 | 10 | |

| 1.125 | 42.5 | 45 | 32.5 | 10 | |

| 30 | 44.5 | 45 | 32.5 | 10 | |

| 32 | 1.250 | 46 | 48 | 32.5 | 10 |

| 33 | 47 | 48 | 32.5 | 10 | |

| 35 | 1.375 | 48 | 50 | 32.5 | 10 |

| 38 | 1.500 | 52 | 56 | 34 | 11 |

| 40 | 56 | 58 | 34 | 11 | |

| 42 | 1.625 | 56 | 61 | 34 | 11 |

| 43 | 59 | 61 | 34 | 11 | |

| 44-45 | 1.750 | 59 | 63 | 34 | 11 |

| 48 | 1.875 | 62.4 | 66 | 34 | 11 |

| 50 | 2.000 | 65.6 | 70 | 34 | 13 |

| 53 | 2.125 | 68.8 | 73 | 34.5 | 13 |

| 55 | 70.8 | 75 | 34.5 | 13 | |

| 2.250 | 71.9 | 78 | 34.5 | 13 | |

| 58 | 75.2 | 78 | 34.5 | 13 | |

| 60 | 2.375 | 75.2 | 80 | 34.5 | 13 |

| 63 | 78.3 | 83 | 34.5 | 13 | |

| 2.500 | 78.3 | 85 | 34.5 | 13 | |

| 65 | 84.2 | 85 | 36.5 | 13 | |

| 68 | 2.625 | 85.5 | 90 | 36.5 | 15.3 |

| 70 | 2.750 | 87.4 | 92 | 36.5 | 15.3 |

| 73 | 2.875 | 90.6 | 97 | 36.5 | 15.3 |

| 75 | 92.7 | 97 | 36.5 | 15.3 | |

| 3.000 | 93.7 | 105 | 36.5 | 15.7 | |

| 80 | 3.125 | 100 | 105 | 36.5 | 15.7 |

| 3.250 | 100 | 110 | 36.5 | 15.7 | |

| 85 | 3.375 | 103.3 | 110 | 36.5 | 15.7 |